Flowflex Copper Press Fittings offer the ideal, cost-effective jointing solution for domestic, commercial & industrial applications.

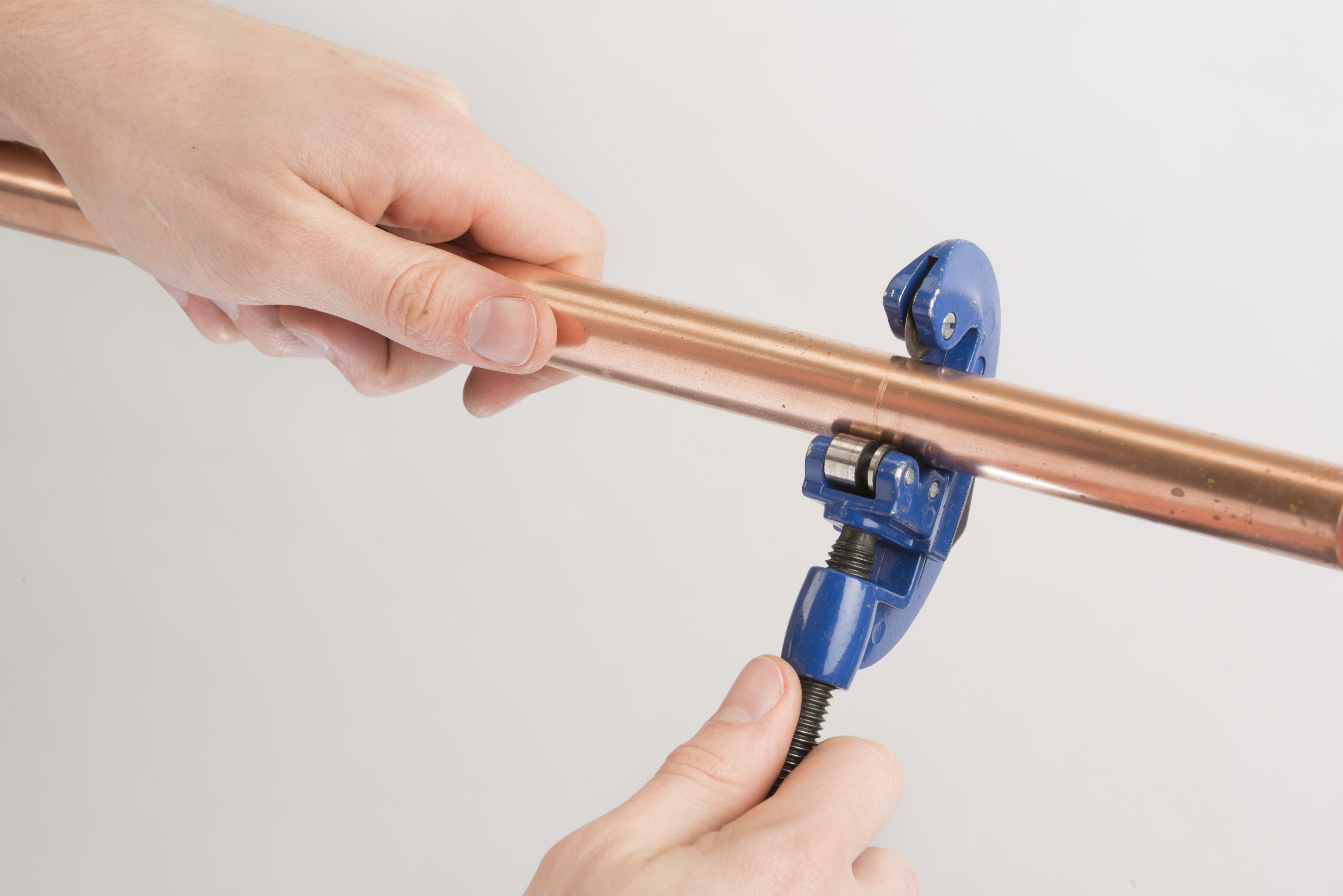

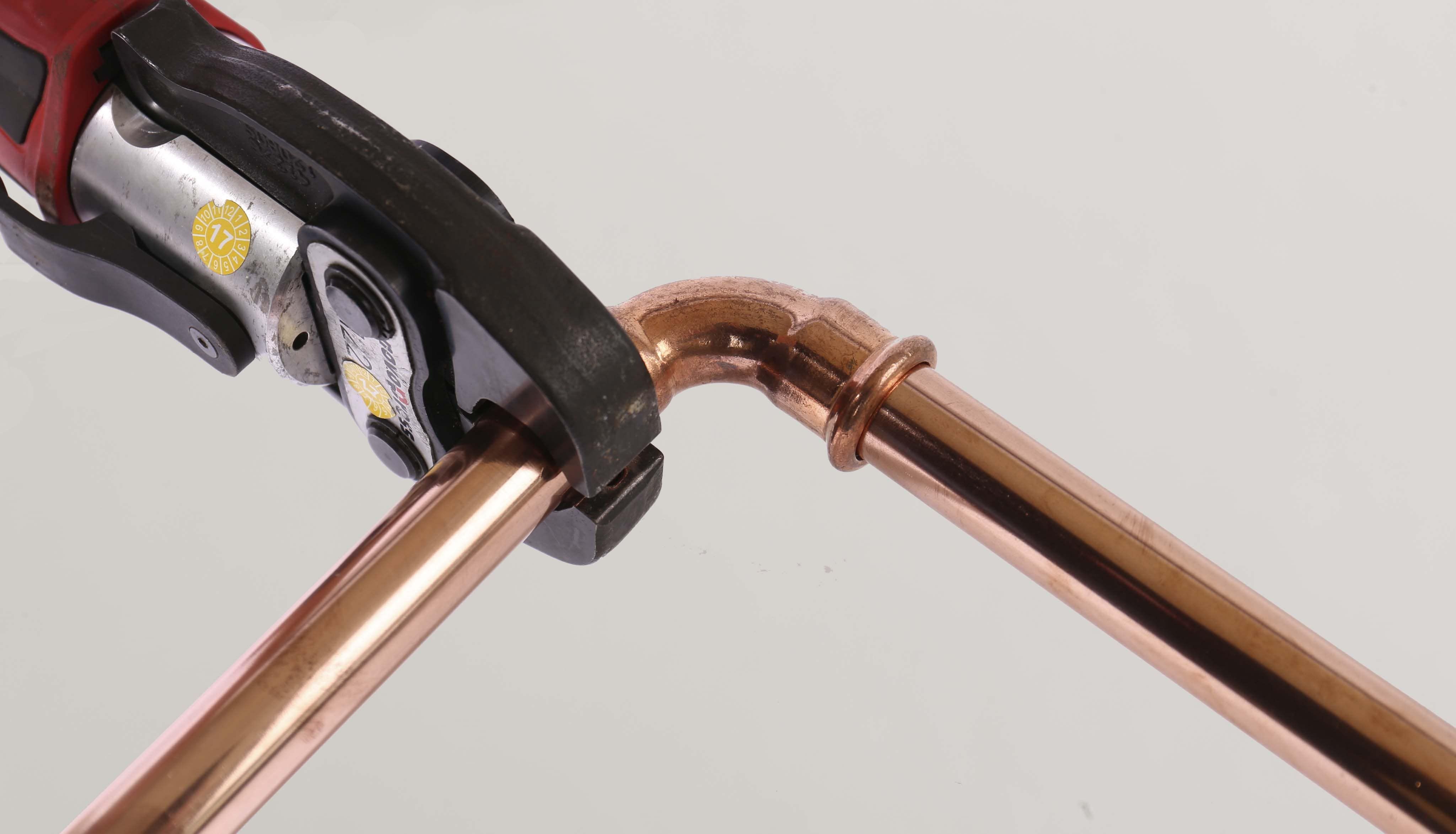

Our complete range of M-Profile Copper Press can be installed using a speedy heat-free jointing technique which creates an aesthetic, secure and permanent joint.

Copper Press Fittings are available in sizes from 15mm to 76mm follow 'M' Profile and are compatible with all 'M' Profile tooling.

Above Ground Applications

- Domestic

- Commercial

- Industrial

- Drinking Water

- Purified Water

- Heating Systems