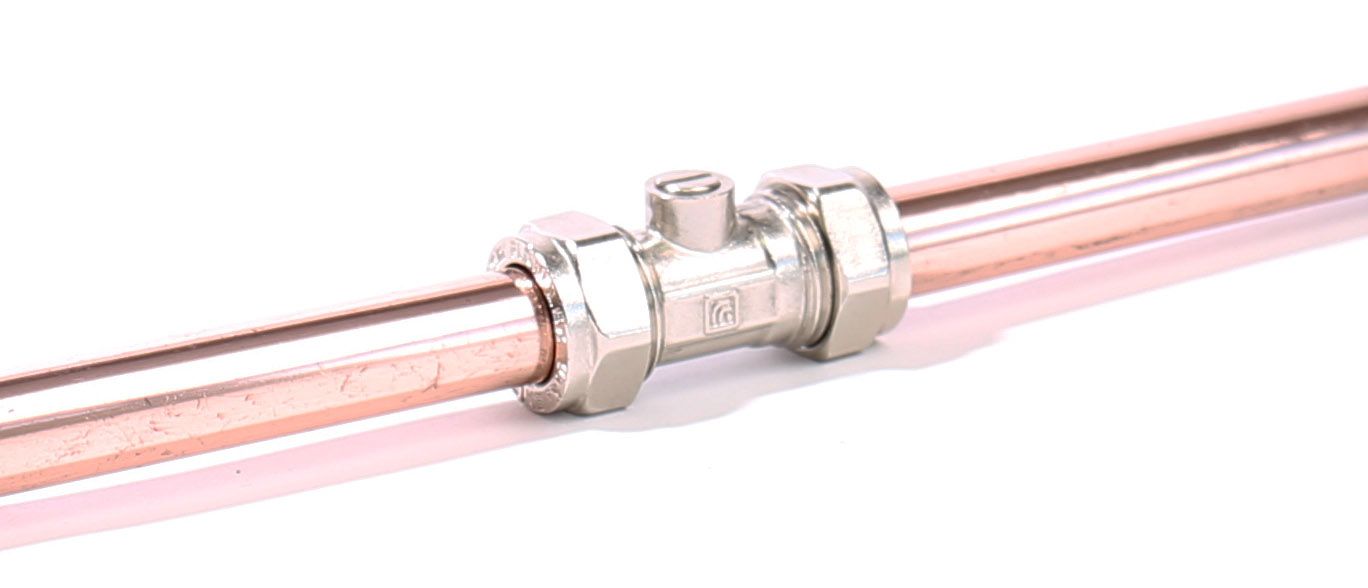

Flowflex Isolation Valves are a quick way of isolating flow on 15mm or 22mm copper pipe water or central heating system. Flow is controlled through a quarter turn action which moves the hole in the ball valve inline or out of line with the flow, preventing or facilitating flow as appropriate.

Isolation Valves are regarded as a long term and reliable solution, performing well after long periods of disuse. An advantage of an Isolation Valve is its quick operation which also makes it ideal for emergency applications. Flowflex Brass isolation valves can be supplied with a chrome finish.

Applications

- Domestic

- Commercial