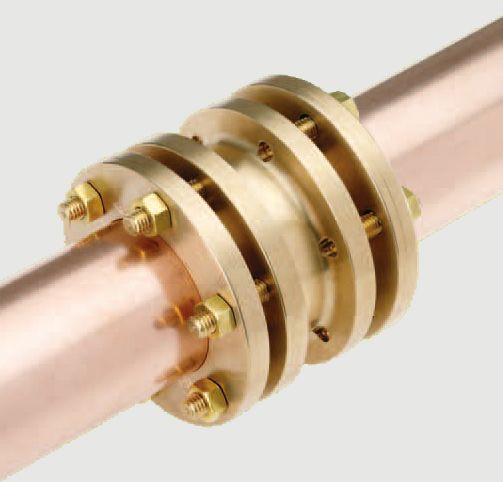

Manufactured to the highest standards in the UK, our complete range of large brass compression fittings, sizes 67mm to 108mm, provides the reliability and quality demanded by todays professional installers. Fittings are designed to join copper pipe creating a heat free mechanical joint upon tightening the various nuts onto the flange faces.

Applications

- Commercial

- Industrial