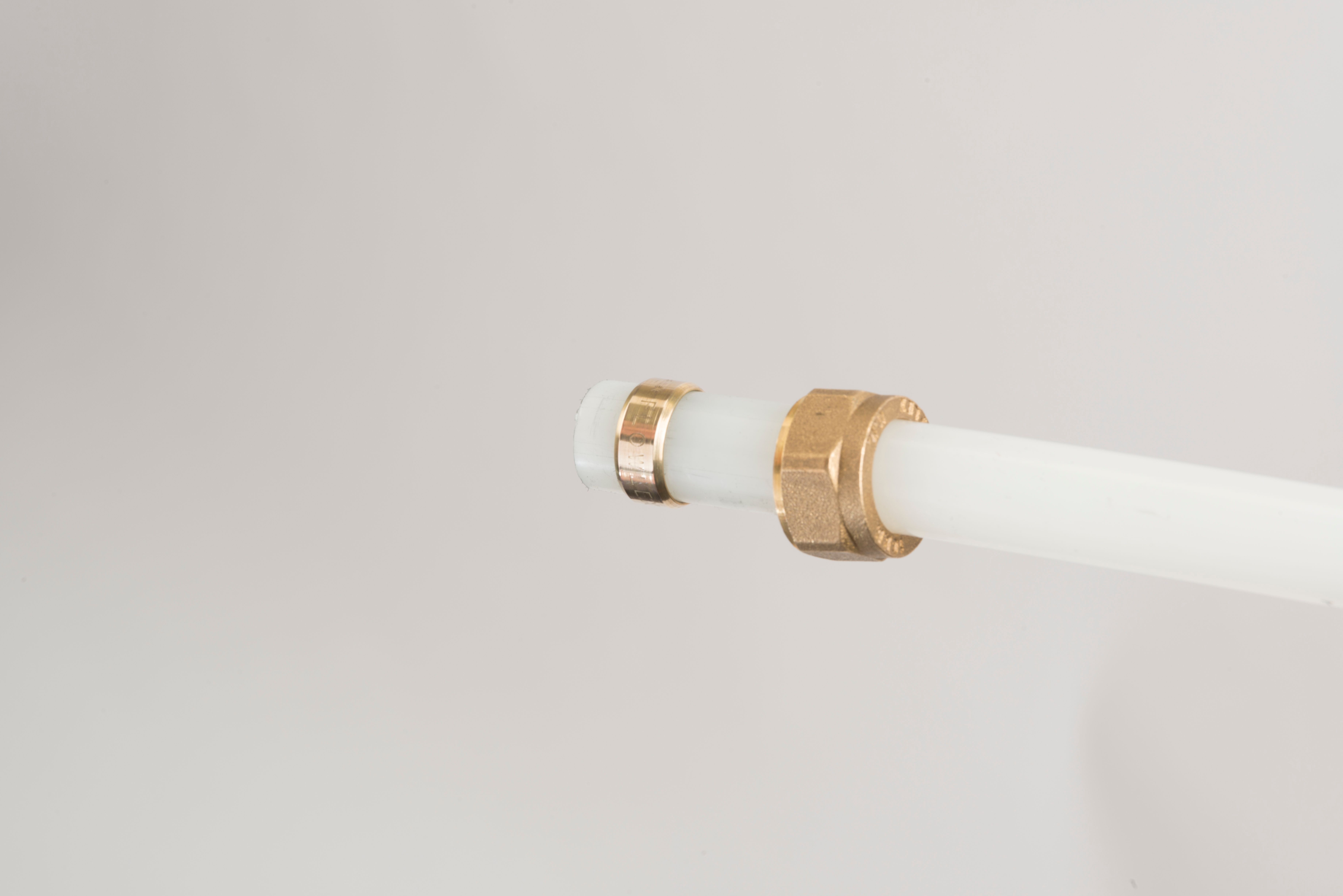

Flowflex PEX fittings is our solution for connecting brass fittings to PEX pipe. PEX Fittings, 16mm to 20mm, come manufactured with an insert and are supplied with a split olive to allow for a firm joint. Our PEX range brings quality and reliability to your localised water system and is suitable for use central heating and underfloor heating systems. Our PEX system range includes Brass Fittings, Valves, Manifolds, Pipe and Pipe Sheaths for a full system solution.

Applications

- Domestic

- Commercial