Solder

Soldered joints depend on capillary action drawing free-flowing molten solder into the gap between the fitting and the tube.

The selection of a solder depends primarily on the operating pressure and temperature of the system. Consideration should also be given to the stresses on joints caused by thermal expansion and contraction.

In the cases of a short run, or a long run with an expansion loop, the stresses caused by a temperature change are usually insignificant.

The 50:50 tin:lead solder is suitable for moderate pressures and temperatures. For higher pressures, or where greater joint strength is required, 95:5 tin:silver can be used. When operating outside of these parameters, please consult us before installation.

Flux

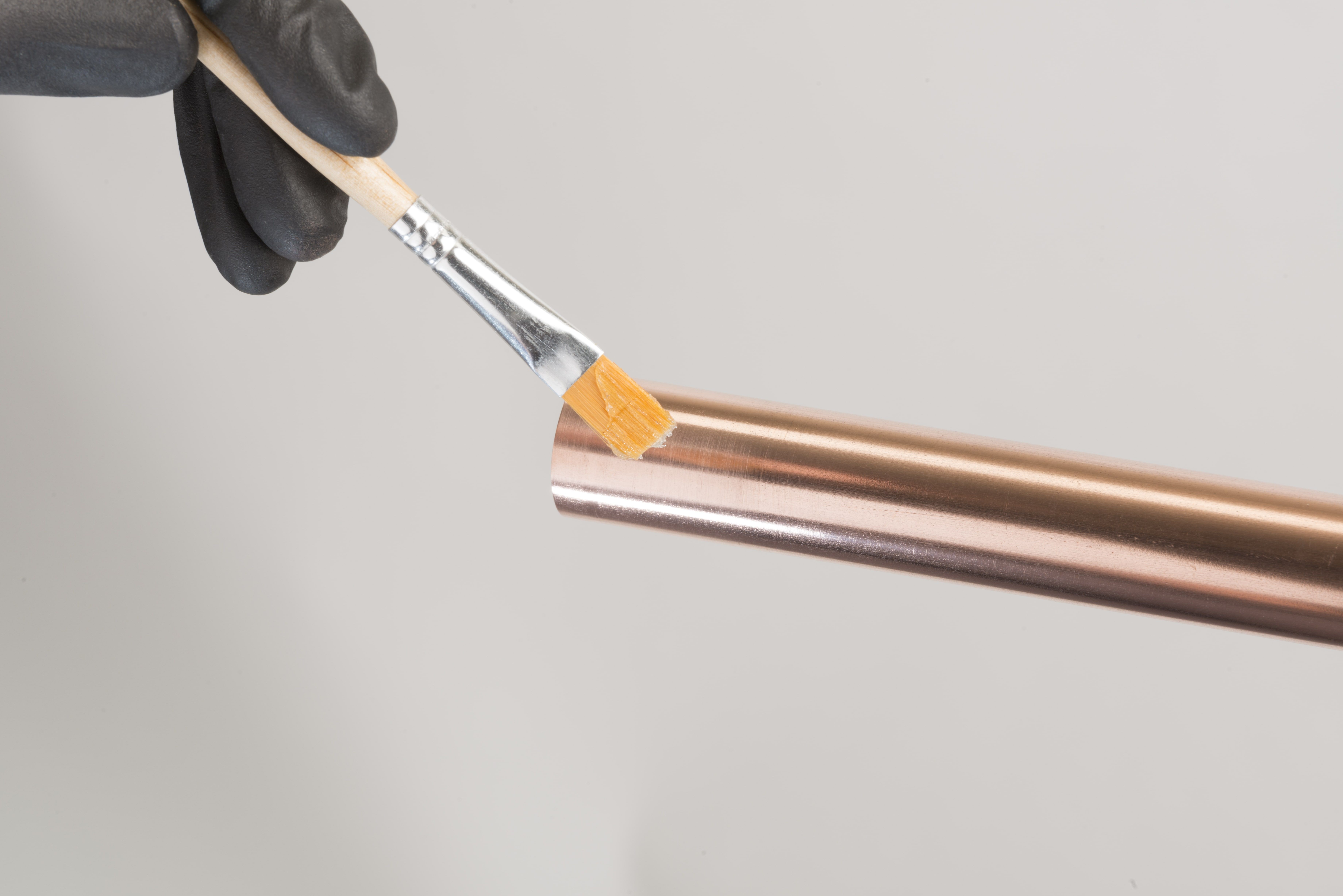

The functions of soldering flux are to protect against re-oxidation of the joint during the soldering procedure, promote wetting that allows capillary action to begin, and to assist in residual oxide removal.

Flux should only be applied to surfaces that have been cleaned using an abrasive cloth. After this, only enough flux to lightly coat the areas should be used, only in the areas where the tube and fitting will overlap. All fluxes should be used sparingly and strictly in accordance with the manufacturer's instructions. The use of excessive flux must be avoided. Some fluxes are more aggressive than others but all fluxes should be considered to be corrosive to some extent.

An oxide film may re-form quickly on copper after it has been cleaned. Therefore, the flux should be applied as quickly as possible after cleaning.