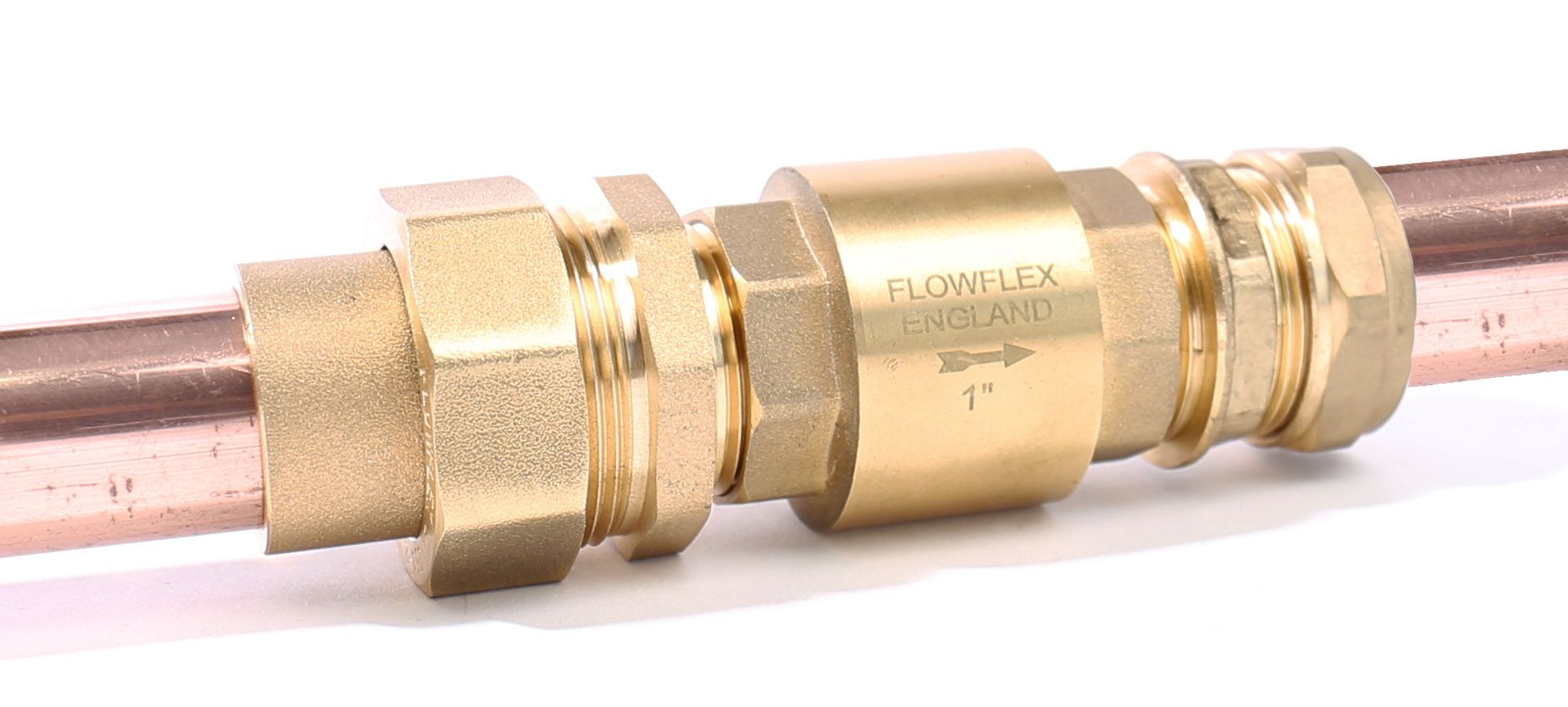

For applications where flow in only one direction is required, Flowflex's Spring Check Valves are available. Our Disc Check Valve designed for a smooth action; the addition of a central guide offers further improved reliability when compared to traditional unguided disc check valves.

Our Brass Spring Check Valves have an advantage in that they can be installed in an either horizontal or vertical position. As upstream pressure increases, the spring-loaded disc is forced open, lifting the disc from its seat to allow flow through the valve.

Applications

- Domestic

- Commercial

- Industrial